Fluid velocity measurement is a critical aspect in various industries, playing a pivotal role in processes such as oil and gas production. The need for accurate and reliable measurements has led to the development of advanced technologies, with electromagnetic flow meters standing out as one of the most precise tools available. This comprehensive guide explores the world of electromagnetic flow meters, shedding light on their principles, applications, advantages, and challenges.

Fluid velocity measurement serves as the cornerstone for numerous industrial processes, influencing the efficiency and accuracy of operations. Whether in chemical processing, water management, or the oil and gas industry, the ability to precisely measure fluid velocity is crucial. This guide focuses on electromagnetic flow meter types, highlighting their significance in achieving unparalleled accuracy and reliability.

Understanding Fluid Velocity

Fluid velocity is a key parameter in various industries, determining the flow rates essential for efficient operations. In the oil and gas sector, precise fluid velocity measurements are imperative for optimizing production and ensuring the integrity of pipelines. Challenges in fluid velocity measurement include factors such as varying fluid properties, environmental conditions, and the need for non-intrusive measurement techniques.

Electromagnetic flow meters operate on the principle of Faraday’s Law of electromagnetic induction. These meters consist of a pipe through which the fluid flows and electrodes that generate a magnetic field. As the conductive fluid passes through the magnetic field, it induces a voltage proportional to its velocity, allowing for accurate measurement. The non-intrusive nature of electromagnetic flow meters sets them apart, as they do not obstruct the flow or require direct contact with the fluid.

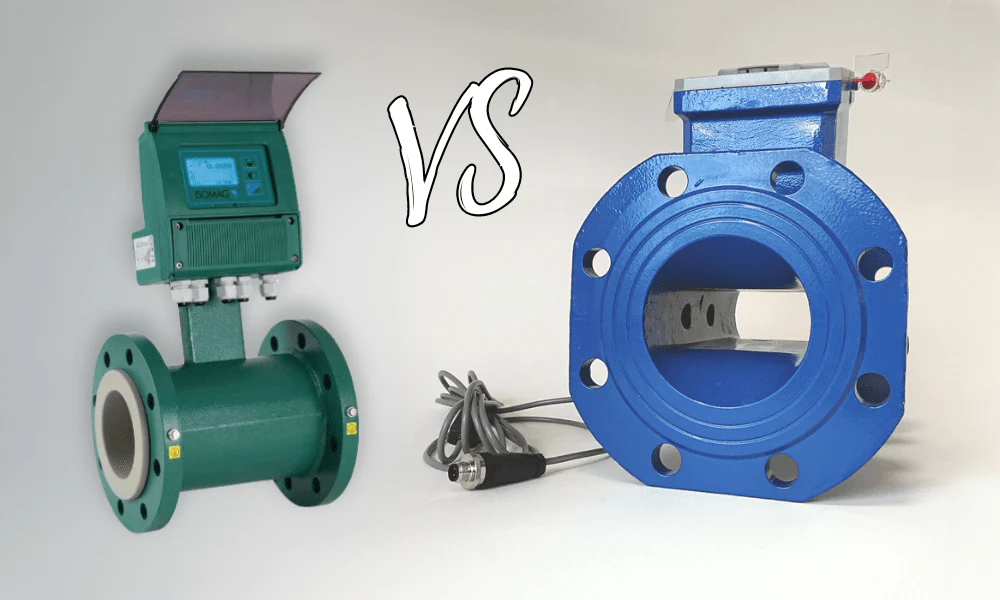

Types of Flow Meters

Comparing electromagnetic flow meters with other types, such as ultrasonic and vortex flow meters, reveals distinct advantages. Electromagnetic flow meters excel in accuracy and reliability, making them particularly suitable for applications where precision is paramount. Unlike traditional methods, electromagnetic flow meters are not affected by the fluid’s composition, viscosity, or temperature variations, providing consistent measurements across different fluid types.

The advantages of electromagnetic flow meters extend beyond their precise measurements. Their non-intrusive nature reduces the risk of contamination, making them suitable for hygienic applications in industries such as food and pharmaceuticals. Additionally, electromagnetic flow meters require minimal maintenance, contributing to cost savings and operational efficiency.

Applications in Oil and Gas Industry

In the oil and gas industry, where accurate fluid velocity measurements are critical, electromagnetic flow meters find extensive applications. From monitoring the flow of crude oil through pipelines to optimizing the injection of chemicals for enhanced oil recovery, these meters play a vital role in ensuring the efficiency and safety of operations. Case studies and success stories showcase the real-world impact of electromagnetic flow meters in this dynamic industry.

Achieving accurate measurements with electromagnetic flow meters involves considering various factors. Environmental conditions, such as temperature and humidity, can influence the meter’s performance. Understanding the fluid’s properties, including conductivity and composition, is crucial for calibration and ensuring reliable results. Regular maintenance and calibration routines further contribute to sustained accuracy over time.

Challenges and Limitations

While electromagnetic flow meters offer numerous advantages, they are not without challenges. Common issues include signal noise, especially in low-conductivity fluids, and the potential impact of external electromagnetic interference. Strategies to overcome these limitations involve proper installation practices, shielding techniques, and ongoing monitoring to identify and address any deviations in measurement accuracy.

Comparing electromagnetic flow meters with other types, such as ultrasonic and vortex flow meters, provides insights into the strengths and weaknesses of each. Electromagnetic flow meters stand out for their high accuracy and reliability, particularly in applications where the fluid’s conductivity is consistent. Understanding the specific requirements of each application is crucial for selecting the most suitable flow meter.

Installation and Maintenance

Proper installation of electromagnetic flow meters is essential for optimal performance. Ensuring a straight run of pipe before and after the meter, avoiding areas with turbulence, and following manufacturer guidelines contribute to accurate measurements. Regular maintenance, including calibration checks and electrode cleaning, enhances the longevity and reliability of electromagnetic flow meters, reducing the risk of measurement errors.

Looking ahead, the future of fluid velocity measurement involves emerging technologies and innovative approaches. Integrating electromagnetic flow meters with IoT and smart systems enables real-time monitoring and remote access to data. Ongoing research aims to further enhance the capabilities of these meters, addressing current limitations and expanding their applicability across diverse industries.

Conclusion

In conclusion, mastering fluid velocity measurement is paramount for the efficiency and success of various industrial processes, with electromagnetic flow meters emerging as a leading solution. Their accuracy, reliability, and non-intrusive nature make them indispensable in applications ranging from oil and gas to pharmaceuticals. As technology advances, the integration of electromagnetic flow meters with smart systems paves the way for a future where precise fluid velocity measurements contribute to optimized and sustainable industrial operations. This comprehensive guide serves as a valuable resource for understanding the principles, applications, and potential advancements in electromagnetic flow meters.